Optimizing Chiller Systems: Frequently Asked Questions

Although they are generally efficient, chillers use a substantial amount of energy, particularly in summer during periods of peak demand. Increasing chiller efficiency helps to reduce operating costs and improve your bottom line. These common questions address a variety of issues regarding chiller performance and operation.

How does a chiller system work?

Chiller system parts include a compressor, an evaporator drum, a condenser drum, pumps, water pipes and a cooling tower. Chilled water moves through a space and removes heat. The warmed water returns to the evaporator drum, where a liquid refrigerant absorbs the heat by changing to a vapor, cooling the incoming water. The compressor increases the vapor’s temperature and pressure. Next, the vapor moves on to the condenser drum, where the heat is rejected from the refrigerant to the condenser water which is then passed through the cooling tower. The refrigerant vapor condenses to liquid, starting the cycle over again.

How is efficiency measured for chillers?

Chiller efficiency is typically measured by the amount of power in kilowatts (kW) required to generate one ton of cooling. Large centrifugal chillers are the most efficient, with ratings often less than 0.6 kW/ton. Screw type and reciprocating chillers can range from 0.55 kW/ton up to 1.5 kW/ton, depending on system design and type. Chillers frequently operate at part load. Integrated Energy Efficiency Ratio (IEER) is an efficiency measurement designed to reflect part-load chiller performance.

What is the proper chilled-water temperature setting for our facility?

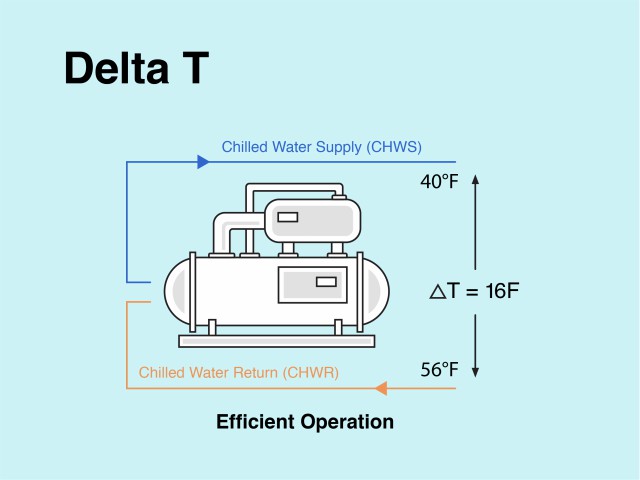

Appropriate temperature settings must balance energy efficiency with building comfort. Keeping the chilled water supply temperature as high as possible saves energy. An estimated 2% of compressor energy savings is possible for every degree of temperature increase. However, this must be balanced against the difference between chilled water supply and return water temperatures (Delta T). Low Delta T forces chilled water pumps to work harder than necessary to produce the needed cooling.

How much energy can you save by installing water-side economizers?

Water-side economizers allow cooling towers to produce chilled water when weather conditions permit. Under the right circumstances, such free cooling can save a lot of energy. In dry, cool climates, water-side economizers can provide a significant amount of overall cooling needs. They are less effective in warmer climates, but they still may be worth the investment.

Should we replace or retrofit our chillers?

The retrofit versus replacement decision is driven by several factors, including efficiency, life-cycle cost, capacity, system demand and any planned building projects. Chillers over 10 years old are often targeted for replacement to improve efficiency. Changes in cooling requirements, however, may result in a new system that’s much smaller in capacity, reducing energy costs even further.

Can you add a variable speed drive (VSD) to an existing chiller and how much will it save?

In many circumstances, installing variable speed drives on chillers can result in significant energy savings. Most existing chillers can be retrofitted with a VSD, although you should consult with the unit manufacturer before installing a new drive.

Now you have the answers you need to identify and fix problems, save energy and improve chiller performance.